Revolutionizing Motor Racing with Hybrid Innovation

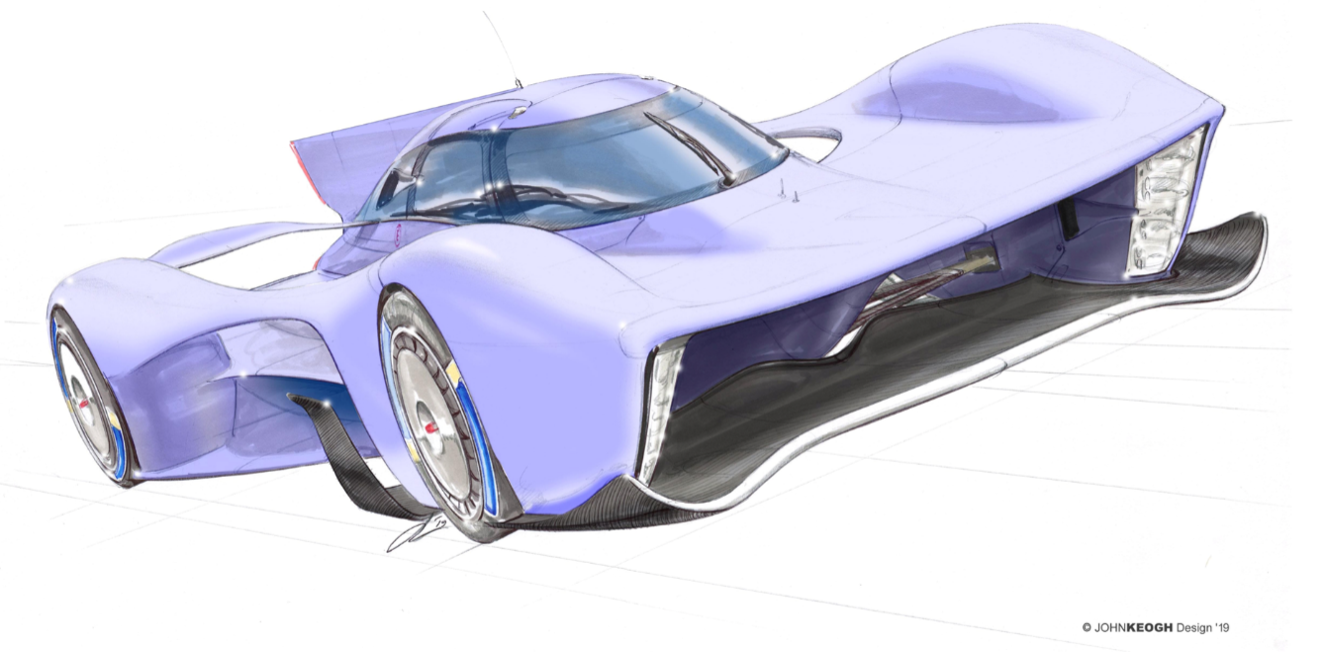

Le Mans Hypercar Prototype

Case study: AIM Le Mans Project

LMH Prototype

Le Mans Hypercar Prototype

The Brief

In 2018, the ACO and FIA announced the introduction of the new LMH (Le Mans Hypercar) Sport Prototype category, set to debut in 2021. This initiative aimed to reduce costs and attract more manufacturers. A few years later, a Japanese second-tier automotive supplier decided to showcase and promote their components by creating their own LMH team.

With plans to debut in 2022, this OEM supplier commissioned Astauto to conduct a feasibility study—assessing the technical and financial requirements for building the cars and participating in the WEC championship with their own LMH entry. Additionally, Astauto was tasked with producing and providing technical support for the proposed WEC team.

Deliverables

After a three-month program, Astauto delivered:

- Performance target estimations: Based on a fully modeled and developed LMH car simulation, incorporating initial targets for aerodynamics, vehicle dynamics, and powertrain specifications.

- BoM creation and PERT chart: A comprehensive Bill of Materials and PERT chart for the design, development, and construction of the LMH car, informed by our experience with LMP1 design and production.

- Budget creation: Utilizing the BoM and partner quotations, we outlined five distinct racing scenarios with corresponding budgets:

- One-car team – 2 Races + Le Mans

- Two-car team – 2 Races + Le Mans

- One-car team – Full WEC Championship

- Two-car team – Full WEC Championship

- Two-car team + spare car – Full WEC Championship

Our approach

Astauto’s strategy for this project comprised the following steps:

- Study of LMH regulations and creation of the Specifications Book: The LMH regulations, introduced in 2021, were based on a concept proposed to the ACO by Sergio Rinland in 2010. Unlike traditional approaches, this concept focused on regulating performance outcomes—such as power output, aerodynamic drag, and downforce—rather than prescribing vehicle design details.

- Power is measured via torque and RPM at the driveshafts, while drag and downforce are homologated through standardized wind tunnel tests. Homologated 3D designs are submitted to the FIA for verification, with random checks during scrutineering at events.

- Although the initial downforce and drag targets seemed achievable based on our LMP1 experience, maintaining maximum efficiency (lift-to-drag ratio) across various speeds and ride heights presented a significant challenge. Our first step was launching a CFD program to evaluate these constraints.

- For power, while achieving peak outputs appeared straightforward, the challenge lay in designing a combined rear ICE and front MGU system capable of consistently operating at maximum allowed power.

- Initial aerodynamic design and CFD program: The project’s Specifications Book outlined ambitious aerodynamic targets. These targets guided the aerodynamic simulations to predict the vehicle’s performance across Le Mans and other WEC circuits.

- ICE and MGU torque-power curve specifications: LMH regulations defined a power curve at the wheels with specified minimum and maximum tolerances. Our simulation model incorporated an ICE with this torque curve and a control system to adjust output when the front motors were activated.

- Simulation program to assess target performance: Using AVL VSM simulation software, we conducted detailed simulations to establish performance targets for the vehicle’s key parameters as outlined in the Specifications Book.

What Our Motorsport Clients Say

“Sergio, I always feel a deep sense of nostalgia when I think about the time we spent together in Formula 1. We were young (it was 1988), full of enthusiasm and with limited resources, yet under your technical leadership, we designed and built a car in a short time that allowed Scuderia Italia and Alex Caffi to hold their own with dignity against numerous experienced competitors. Then our paths diverged, but I will always be grateful for the contribution you made to the growth of Dallara Automobili, and I am pleased to see that your expertise continues to enable you to successfully tackle new challenges.”

Gianpaolo Dallara

Dallara Automobili

“Over the years, AVL has been proud to collaborate with Astauto, a dedicated and innovative user of our simulation software. Their invaluable feedback and commitment have significantly contributed to the evolution and refinement of our tools, ensuring they meet the highest industry standards. Astauto’s proactive approach to leveraging our technology has not only enhanced their own projects but has also played a key role in advancing simulation capabilities for the broader Automotive and Motorsport engineering community. Together, we have fostered a relationship rooted in mutual growth, technical excellence, and shared vision for innovation.”

AVL List GmbH

“We first had the pleasure of working with Sergio when he was at Brabham in 1989 and 1990, supplying Judd EV 3,5 litre V8 engines for the 2 Brabham BT58 cars driven by Martin Brundle and Stefano Modena. Whilst it was a difficult time for the team Sergio had in fact designed an excellent F1 car which achieved a 3rd place at the Monaco GP that year and further enhanced his reputation as a car designer. A further collaboration was in 2008 for the Epsilon LMP car which sadly never came to fruition but was as ever a pleasure due to Sergio being responsible for the engineering and design, displaying a high level of competence and friendly liaison throughout.”

John Judd

JUDD Power