REVOLUTIONIZING TRANSPORT WITH ELECTRIC AND HYBRID INNOVATION

Electric and Hybrid Solutions for Commercial Vehicles

Explore how Astauto is pioneering the future of commercial vehicles with cutting-edge electrification technology, designed to reduce emissions and enhance efficiency.

Pioneers in Engineering Excellence

Astauto Ltd proposes the concept of a series hybrid trucks and buses with a small displacement engine that powers a generator to keep the batteries sufficiently charged to deliver the necessary power.

A series hybrid system is proposed because, in countries and territories where these vehicles are used, the necessary charging infrastructure for a purely electric commercial vehicles may not exist.

Building a vehicle with this architecture allows for the possibility of creating a purely electric system powered by batteries only and/or hydrogen fuel cells in the future or for other applications, instead of the internal combustion engine-generator-battery system of the series hybrid. Initially, the series hybrid system would significantly reduce fuel consumption and the consequent emission of harmful gases into the atmosphere.

Our Advanced Development Services

Hybrid Vehicle Development

Specializing in the design and development of electric and series hybrid vehicles, we provide tailored solutions that could integrate small displacement engines with generators, optimizing battery performance for public transport and commercial vehicles applications.

Simulation and Analysis

Utilizing industry-leading simulation software, we analyze vehicle performance, efficiency, and drivability, ensuring optimal design and functionality from concept to prototype.

Innovative Hybrid Solutions

Reduced Emissions

Our series hybrid vehicles concepts are designed to significantly cut down on emissions, making them an environmentally friendly choice for commercial and public transport applications in countries and regions where electric charging infrastructure is still not fully developed.

Future-Ready Electric and Hydrogen fuel cells Systems

With the potential for full electrification, our hybrid systems are poised to evolve into purely electric or hydrogen fuel cells solutions as infrastructure develops.

Enhanced Efficiency

By optimizing energy use, our vehicles ensure maximum efficiency, reducing fuel consumption and operational costs.

What Our Clients and Partners Say

“Since 2016, Sergio and his team have been invaluable partners in our expansion into the South American market for electric buses. Their deep expertise and strategic insights helped us navigate this evolving sector while also playing a crucial role in the design and development of electric buses tailored for both South America and the UK. Now, as we venture into agricultural machinery electrification for the global market, their continued support and innovative thinking remain instrumental in driving forward our vision.

Their dedication, technical knowledge, and ability to adapt to emerging opportunities make them an outstanding collaborator in shaping the future of sustainable transportation.”

Ian Foley

Chief Executive Officer

Equipmake Ltd

“From the very beginning of our journey developing the REE Corner and REE Platform, Sergio and Astauto have been invaluable partners to our R&D efforts. Their expertise in vehicle performance analysis, combined with advanced simulation tools, allowed us to make informed decisions on critical components—including motors, batteries, tyres, and aerodynamics. Thanks to their support, we rigorously evaluated our small to medium electric delivery trucks across a variety of drive cycles and typical mounting roads, ensuring optimal performance and efficiency. Their contributions have been instrumental in shaping our vehicles into cutting-edge solutions for the industry.

We couldn’t have asked for a more dedicated and insightful partner”

Ahishay Sardes

Director & Chief Technology Officer

REE Automotive Ltd.

“Over the years, AVL has been proud to collaborate with Astauto, a dedicated and innovative user of our simulation software. Their invaluable feedback and commitment have significantly contributed to the evolution and refinement of our tools, ensuring they meet the highest industry standards. Astauto’s proactive approach to leveraging our technology has not only enhanced their own projects but has also played a key role in advancing simulation capabilities for the broader Automotive and Motorsport engineering community. Together, we have fostered a relationship rooted in mutual growth, technical excellence, and shared vision for innovation.”

Mario Oswald

Team Leader

Engineering & Technology Powertrain Systems

AVL List GmbH

“Sergio’s contributions to Agrale have been instrumental in driving innovation and excellence. His expertise, dedication, and visionary approach have consistently elevated the team and its achievements.”

Edson A S Martins

Director

Agrale S.A.

Case study: Successful Implementation in Logistics

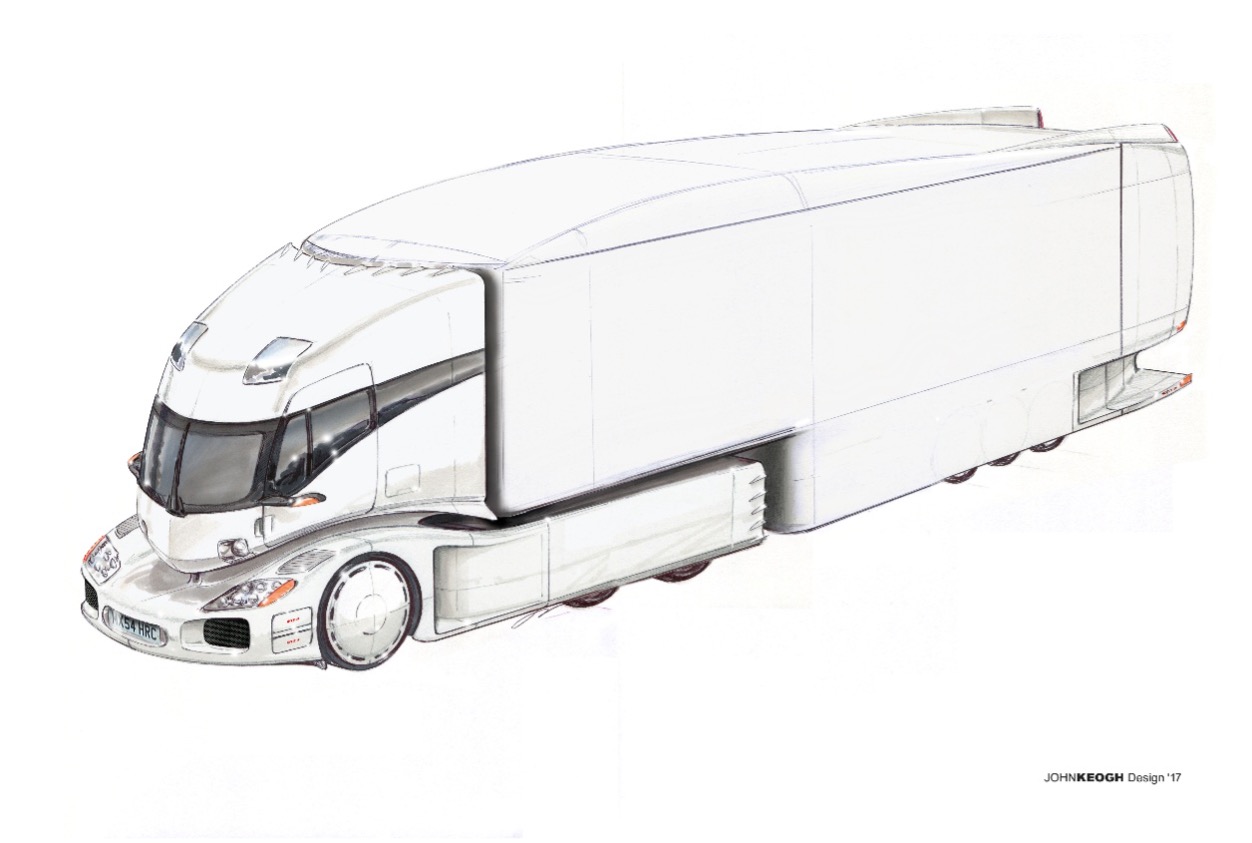

HYBRID Truck

Series Hybrid Electric HGV1 Truck

The Brief

In 2016/2017, under the Horizon 2020 program—EU’s research and innovation funding initiative spanning 2014–2020 with a budget of nearly €80 billion—Astauto assembled a consortium of seven companies (four from the UK, two from Italy, and one from Austria).

The goal was to design and develop an HGV1 truck and trailer featuring a Series Hybrid powertrain, low aerodynamic drag design, and low rolling resistance tyres to reduce fuel consumption and CO2 and NOx emissions. The project, titled ‘Aero Truck,’ had an allocated budget of approximately £14 million.

Deliverables

By the end of the project, Astauto and the consortium achieved the following deliverables:

- Submission of the Horizon 2020 application.

- Initial concept aerodynamic design.

- Initial concept aluminum chassis design.

- Preliminary powertrain specifications, based on WLTP drive cycle simulations at full GVW.

Our approach

Astauto’s approach for the ‘Aero Truck’ project involved the following steps:

- Formation of the Consortium:

- Astauto: Project coordinator, integrator, and vehicle designer.

- Equipmake Ltd: Hybrid electric powertrain provider.

- TotalSim Ltd: Aerodynamic designer and developer.

- Eddie Stobart Ltd: HGV operator and prototype tester.

- BSim SRL: Simulation software provider.

- YCom SRL: Composite manufacturer for the tractor cabin.

- Piotr Bilogan GmbH: Structural calculation specialist.

- Application to the Horizon 2020 Program: The consortium prepared and submitted the application to the EU offices in Brussels by February 1st, 2017.

- Proposal of Project Objectives:

- Develop a low-drag aerodynamic cab and trailer.

- Design the cabin with pedestrian and driver safety in mind.

- Incorporate a central driving position.

- Engineer the chassis and cabin using a combination of aluminum and composite materials for reduced weight.

- Integrate 4 to 6 in-board electric motors, depending on axle configuration.

- Include a gas turbine generator range extender.

- Utilize torque vectoring technology.

- Achieve 40% fuel consumption reduction, 40% CO2 emissions reduction, and 70% NOx emissions reduction.

- Employ HGV low rolling resistance tyres.

Post-Project Comment

Despite over a year of dedicated effort by all parties, the EU ultimately declined the funding request, deeming the project overly ambitious. However, as of 2025, long-haul HGV trucks from the USA and China are being produced following the same principles proposed in the ‘Aero Truck’ concept—a testament to its forward-thinking vision and relevance.

Case study: Series Hybrid City Bus

AGRALE HYBRID MINI BUS FOR BRAZIL

Series Hybrid City Bus

The Brief

Our client, a leading manufacturer of buses and trucks in South America with production plants in Brazil and Argentina, has been producing electric city buses for several years, catering to major cities across South America.

However, for smaller cities and towns where the local electric grid cannot support the required charging infrastructure, the client commissioned Astauto to conduct a study on developing a city bus with a Series Hybrid propulsion system, aiming for production by 2025.

Our approach

Astauto’s methodology for this project included the following steps:

- Defining specifications and attributes of the current vehicle: We modeled and simulated the current Diesel bus to identify key attributes and performance metrics.

- Analyzing power and energy needs for typical operations: We conducted a comprehensive analysis of power and energy requirements for various drive cycles and operating conditions while maintaining the vehicle’s size and weight.

- Developing a virtual model of the electric/hybrid propulsion system: Using advanced modeling tools, we created a detailed virtual model of the power system and vehicle characteristics, simulating performance and efficiency.

Deliverables

Astauto delivered a complete set of electric/hybrid power system specifications, validated by simulation results. These specifications included:

- Traction motors.

- The internal combustion engine for powering the generator.

- The generator itself.

- Battery systems.

- Hybrid control system logic.

Based on the simulation results, we developed and validated propulsion system specifications to ensure they met the desired performance criteria.

In collaboration with suppliers, Astauto also conducted cost estimations and prepared a detailed bill of materials to support the construction of the first prototype. The goal is to have a fully developed prototype ready by the second half of 2025.